"A step towardsa beautiful world,

Hwa Shin Special Textile Filter will come together."

PP, PET, NYLON and other special materials such as Aramid, PPS and Glass are woven into fibers and used as industrial materials.

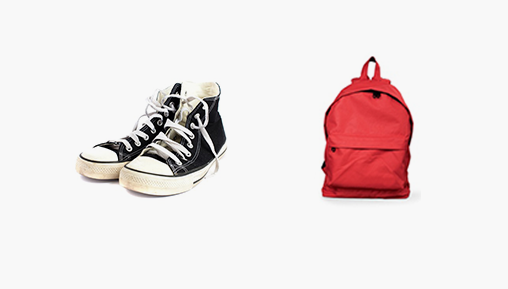

* Each filter bag can be made up to customer’s requirement.Thick and heavy fabrics are generally used to manufacture shoes, bags, code fabrics for rubber belts and etc.

Also called cotton fabric. Costs less than the other textiles, and feels good against the skin as it absorbs sweat and moisture well. It is therefore widely used and is absolutely necessary for various daily necessities, such as shirts, sheets, cotton pockets, and towels. Its form, however, is unstable, and it easily gets creased or shrinks during wear or washing.

After nylon, polyester is the strongest fabric when pulled, and its strength does not change even when wet. It especially recovers well from creases, as much as wool, and also recovers well from wetness. It does not have good moisture absorption, is hardly flexible, and dries easily, so it can be worn right after washing. It is thus good as a shirt material. It also has properties similar to those of sheep wool and therefore largely contributes to the development of new fields, such as formal men’s wear materials mixed with wool or other fibers.

A synthetic material such as kanekalon (created with a 1:1 ratio of vinyl chloride and acrylonitrile) that is made with polymers such as polyacrylonitrile as materials. It is completely melted in a solvent and radiated with a dry or moist method. It later grows tenfold, is heat-processed, and is usually created as a staple. It is made bulky and then made into a combined fiber again for permanent density. This process gives it properties similar to those of wool, and the material is used to make sweaters, undergarments, and blankets. Its tensile strength is 4 g (per denier), its moisture absorption rate is 2%, its weight is around 1.15 (1.27 for kanekalon), and its vitrification point is around 190℃. It is especially used for tents as it is light-resistant. It is warm and light, does not easily crease, and is thermoplastic. It is generally drug-resistant and is not affected by bugs or fungi. It should be washed with a neutral detergent and ironed at 120℃.

The fiber is brown or green, and shiny. It cannot be bleached and is therefore used for making clothes less often than cotton, and is appropriate for multiple other uses, such as for burlap ropes and electric clothing fiber.

Hemp and linens have been used for long to make sails for boats. Sailcloth and canvas are terms that mean the same thing. After the power loom was invented, canvas could be made with linen, hemp, jute, and cotton, and these fibers were also sometimes mixed. When using linen, two warp threads are used so that the textile can endure pressure or rough use. Canvas is used for fishing/hunting/golf/ other sports’ bags, game/racing/sailing sneakers, tents, and mailbags. Canvas woven with linen and cotton is treated with tar and is used to cover goods at railways and docks. Linen or jute canvas yarn is usually double-twisted yarn with two or more threads, and a single-line layout is used to create a uniform thickness. The textiles are usually plain-woven, but special weaving methods are used when gaps are necessary. Artist canvases that are woven with a single warp thread are much lighter than sail canvases. The best-quality canvases are made with around-25-cm-long cream-colored or bleached linen. The surface is preprocessed for drying if woven with a loom.

Nylon textile

The main types of nylon are nylon 6 and 66. Nylon is a chemical fiber that is relatively light (weight: 1.14), so it does not crease easily and has good wash-and-wear properties. As its early elasticity coefficient is low, it easily increases but recovers well compared to other fibers, and is drug-resistant (resistant to strong acids), so it is not affected by fungi or moths. Its resistance grows weaker, however, with UV rays, and the fiber has the disadvantage of brominating when old. It is used for clothes, tire cords, carpets, ropes, computer ribbons, parachutes, plastic, adhesives, etc.

Polyurethane textile

Polyurethane high molecules are created into fibers. The soft segment with relatively low cohesive energy and the hard-segment-block ball polymers with large cohesive energy combine and create physical union between the molecules, making it a chemical fiber that maintains its strength, similar to rubber, and giving it a 92-96% elasticity recovery rate. It is often used for women’s underwear, panty hose, swimwear, various types of sportswear, outerwear, etc., as well as for medical purposes.

Polyvinyl alcohol fabric

Polypropylene has a very low weight and absorption rate, unlike other synthetic fibers, and its melting point is appropriately high (for which reason it has many different uses) but is low enough to heat weld more easily than other synthetic materials can. Therefore, it is appropriate for the manufacture of melt-blown non-woven fabrics. As it consists only of carbon hydrogen, it has no polarity and has high resistance against dirty substances with polarity, which is an important property for carpets and furniture. It is often used for furniture (carpets), as an industrial material (ropes, civil-engineering construction tools), and as a non-woven material. Wicking, which is good for transferring moisture, is a property that is used for its recent main development as a light sportswear material.