"A step towardsa beautiful world,

Hwa Shin Special Textile Filter will come together."

It is a product used in mines, stone mountains, waterworks, steelworks, etc. as a filter product for filter presses.

* Each filter bag can be made up to customer’s requirement.A fabric that is used to filter out fine solid particles inside a liquid

Application

Mines, coal mines, food industry, sewage, cooking oil, carbon fiber, refining, chemicals, drug industry, dyes, pigments, etc.

Types of equipment that use filter cloth

Belt press, Drum filter, Rotary disc filter, Rotary table filter, Reef filter, Filter press, Horizontal disc filter, Centrifugal separator filter

Filter media

PE, PP, Dry, Cotton, Nylon and Etc.

Types

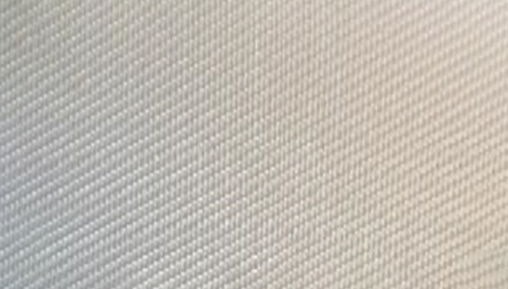

Non-woven fabrics, woven fabrics, mesh fabrics

| Mono / mono | Mono / multi | Multi / multi | |

|---|---|---|---|

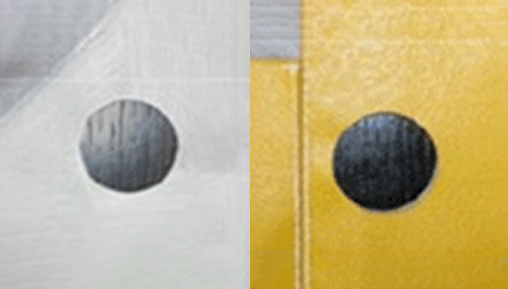

| Feature | 1. Rubber/Cloth Barrel Neck 2. Velcro Fastener 3. Welded PP Eyelet 4. Rubber coating of Felt seal stitching 5. silicon, urethane coating on the edge |

||

| Types | 1. Double Fabric with Rubber (Special cloth) Neck 2. Overhang Cloth 3. End & Front cloth 4. Belts for tower press |

||

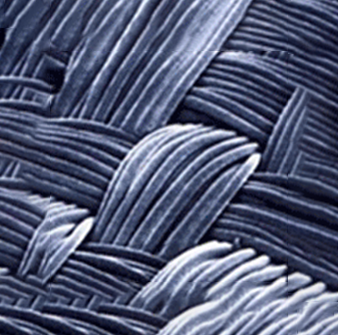

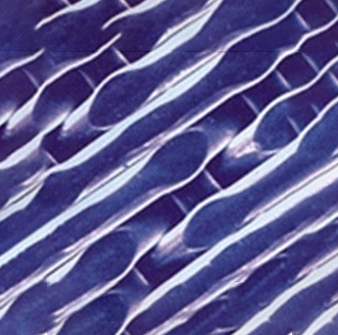

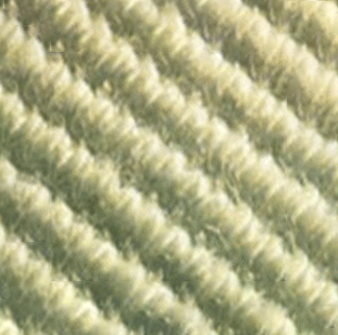

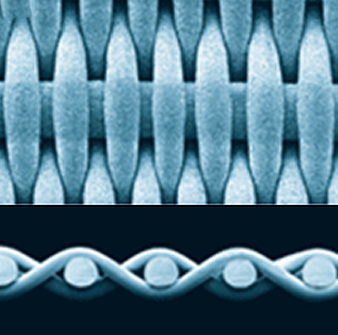

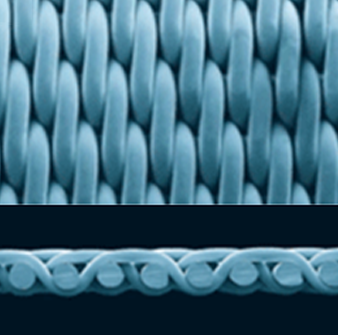

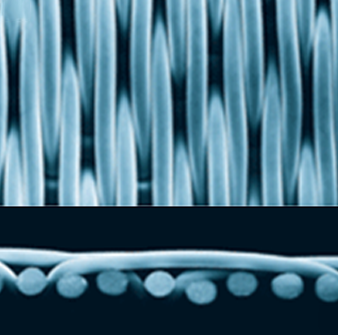

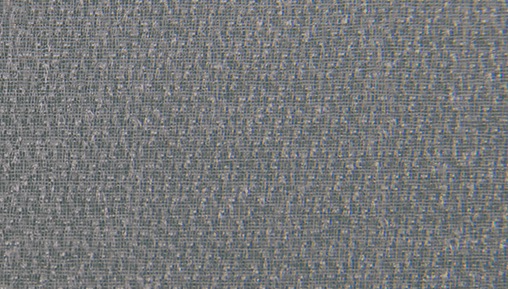

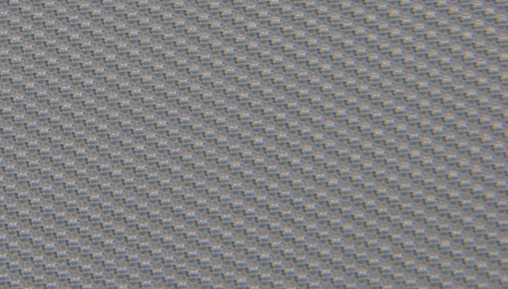

1. Multi filament / 2. Mono filament / 3. Staple fiber

from the left 1 / 2 / 3

from the left 1 / 2 / 3 Multi filament

Multi filament Mono filament

Mono filament Staple fiber

Staple fiber Plain reverse dutch weave

Plain reverse dutch weave Twill

Twill Satin

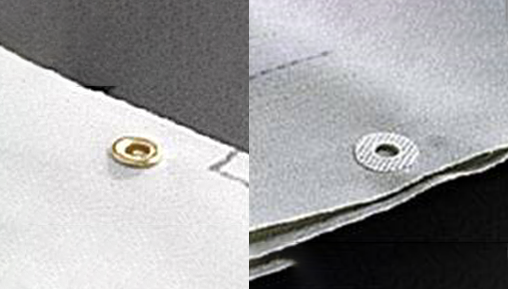

Satin Rubber neck / PP neck

Rubber neck / PP neck eyelet

eyelet Urethane or silicone coating on the edge

Urethane or silicone coating on the edge velcro / string

velcro / stringMono filament fabric is woven fabric, web structured filter cloth with a piece of extruded filament , which is filter cloth of next generation that expanding market strength rapidly because of it’s better filtration efficiency compare with existing traditional non-woven fabric or multi filament fabric.

Existing filter cloth used in filtration process (existing process) has trouble to change filter cloth often, because of clogged mesh when it is used for certain period, while our mono filament fabric can be used for a time more than 3~4 times of current use without clogging of mesh with constant flow rate, due to excellent cake detachability and washability, since it was made from excellent calendaring and weaving technology. It also has stable filtration capacity due to enhanced stability made by special heat treatment.

Application

- Collection process of high value added products

- Collecting of submicron particle process

- Filtration process that requires continuous operation without clogging of mesh

- Process which needs lowering moisture content

- Process which frequently cleans because of bad cake detachability

- Process tries to skip second filtration process by minimizing impurity of filter fluid.

- Process requires changing filter cloth frequently as filter cloth is enlarged or shrunk.

- Process which wants to reduce Pre-coating agent Generally woven filter cloth

PP mono type cloth

PP mono type cloth Nylon mono type cloth

Nylon mono type cloth| weight (g/m²) |

thickness (mm) |

Air permeability (cc/cm²/sec) |

Tensile strength (kg/5cm) MD/CD |

Burst strength (g/m²) |

Using temperature (g/m²) |

finish | application | materia | |

|---|---|---|---|---|---|---|---|---|---|

| Cotton 20s/6X6 |

785 | 1.33 | 1.0 | 42.6 255.7 |

127.7 | ~ 130 | NONE | OIL 정제 (비누,식용유,폐유) |

COTTON |

| PE 20s/6X6 |

833 | 1.3 | 1.1 | 619.1 343.7 |

Over 50 | ~ 135 | TENTERED | 염료, 안료,식품OIL 정제 | P.E |

| PE20s/2X3 (삼능직) |

318 | 0.62 | 13.9 | 182.4 178.7 |

41.3 | ~ 135 | TENTERED | 집진용 | P.E |

| Nylon | 590 | 0.99 | 2.7 | 780.4 500.9 |

Over 50 | ~ 95 | TENTERED | 도자기원료 정제 |

NYLON |

| Nylon 210D |

253 | 0.49 | 30 | 347.7 135.3 |

38.5 | ~ 95 | TENTERED | 도자기원료 정제 |

NYLON |

| PP450D | 420 | 0.85 | 3.8 | 341.1 202 |

35 | ~ 90 | TENTERED | 요업용 폐수처리용 |

P.P |

| PP450D (100X42) |

330.9 | 0.8 | 16 | 240.9 92.6 |

Over 50 | ~ 90 | TENTERED | 염색공장 폐수처리용 |

P.P |

| PP1800D | 575.7 | 1.17 | 2.0 | 455.6 319.2 |

Over 50 | ~ 90 | TENTERED | 제품회수용 폐수처리용 |

P.P |

| PP900D | 516 | 1.0 | 2.3 | 493.8 250.4 |

50 | ~ 90 | TENTERED | 제품회수용 폐수처리용 |

P.P |

| PP900D G (Drum Air Filter) |

416 | 0.90 | 9.1 | 456.8 249.4 |

50 | ~ 90 | TENTERED (Heat treatment) |

제품회수용 폐수처리용 |

P.P |

| SIZE : 2500W X 8500L X 1T | |||||||||

| seagull | 546 | 1.46 | 43.4 | 402.6 254.1 |

Over 45 | ~ 90 | TENTERED | 폐수처리용 | P.P |

| Double layer | 645.8 | 1.19 | 1.5 | 511 299 |

Over 50 | ~ 90 | TENTERED | 안료, 염료생산 | P.P |

| AIR-Filter | 275 | 0.5 | 9.3 | 209.7 151.4 |

424 | ~ 130 | TENTERED | 대형 집진기, Bag-Filter용 | P.P |

| Double layer coating | 625 | 1.1 | 0.7 | ~ 85 | Boh sides melted |

염료, 안료여과용 |

P.P | ||

| PP450D coating |

430 | 1.0 | 0.9 | ~ 90 | Boh sides melted |

염료, 안료여과용 |

P.P | ||